-

CNC machine tools

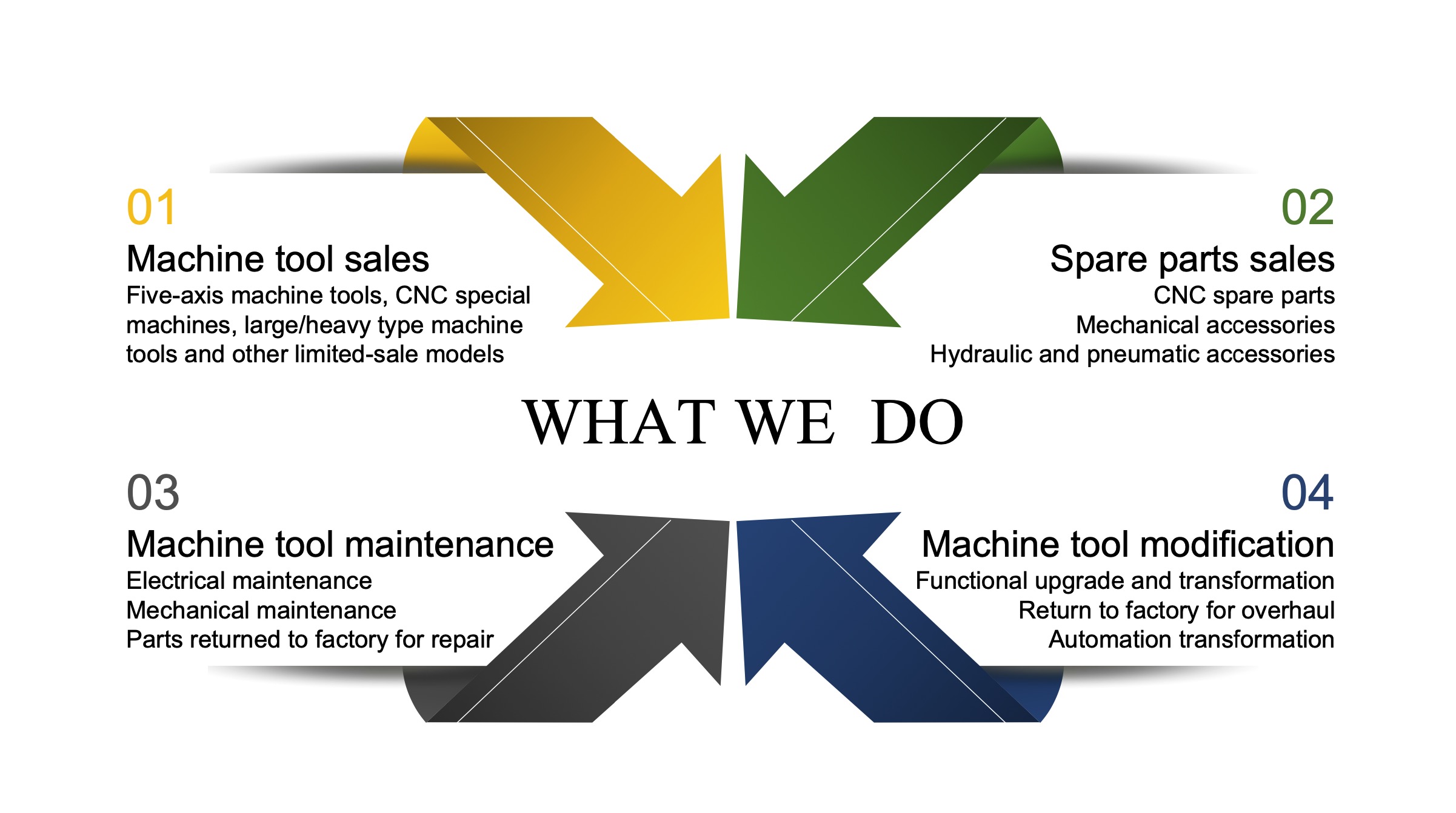

In view of the demand for transformation and upgrading of the manufacturing industry, Z-source Technology (Hong Kong) Limited. selects CNC machine tool products from top domestic and foreign brands, covering multiple fields such as precision processing and intelligent manufacturing. We not only provide high-quality equipment, but also provide professional technical support and after-sales service to help manufacturing companies improve production efficiency and achieve product upgrades.

- Machine Tool Maintenance (Professional & Efficient)

Overview

- 1. Electrical Maintenance: Remote online diagnosis, remote guidance for spare parts replacement

- 2. Mechanical Maintenance: Cooperation with local service partners to provide technical training and skill authorization

- 3. Component Return-to-Factory Maintenance: Vulnerable parts such as electric spindles and attachment heads are sent back to domestic facilities for repair and testing

Electrical Maintenance

For electrical faults, we rely on the remote technical support team + manufacturer technical experts + local service partners to provide remote guidance troubleshooting services and remote online diagnosis services based on alarm prompts. Ensure that routine equipment faults are quickly resolved.

| Title | Description |

| Remote Guidance for Fault Handling | Locate the problem source by referring to maintenance manuals based on system alarm prompts, and replace spare parts step by step until the fault is resolved |

| Remote Online Diagnosis Service | For network-enabled equipment, utilize remote diagnostic networks to organize multiple technical experts for online remote diagnosis, quickly locating and resolving issues |

Mechanical Maintenance

For mechanical failures, we cooperate with local service providers to carry out systematic maintenance skills training, assessment and technical authorization for on-site service personnel, and provide machine tool users with regular mechanical failure problems. On-site inspection and processing services. On-site handling of mechanical faults such as motors, belts or screws.

Component Return-to-Factory Maintenance

We provide return-to-factory repair services for detachable core functional components such as electric spindles, attachment heads and other vulnerable parts. These parts are sent back to domestic facilities through designated professional logistics channels, coordinating with the manufacturer's official channels to complete the Maintenance and perform factory inspections before return. This ensures successful restoration of component performance and provides warranty service. Electric spindle brands include: Renaud, Kessler, etc.