-

CNC machine tools

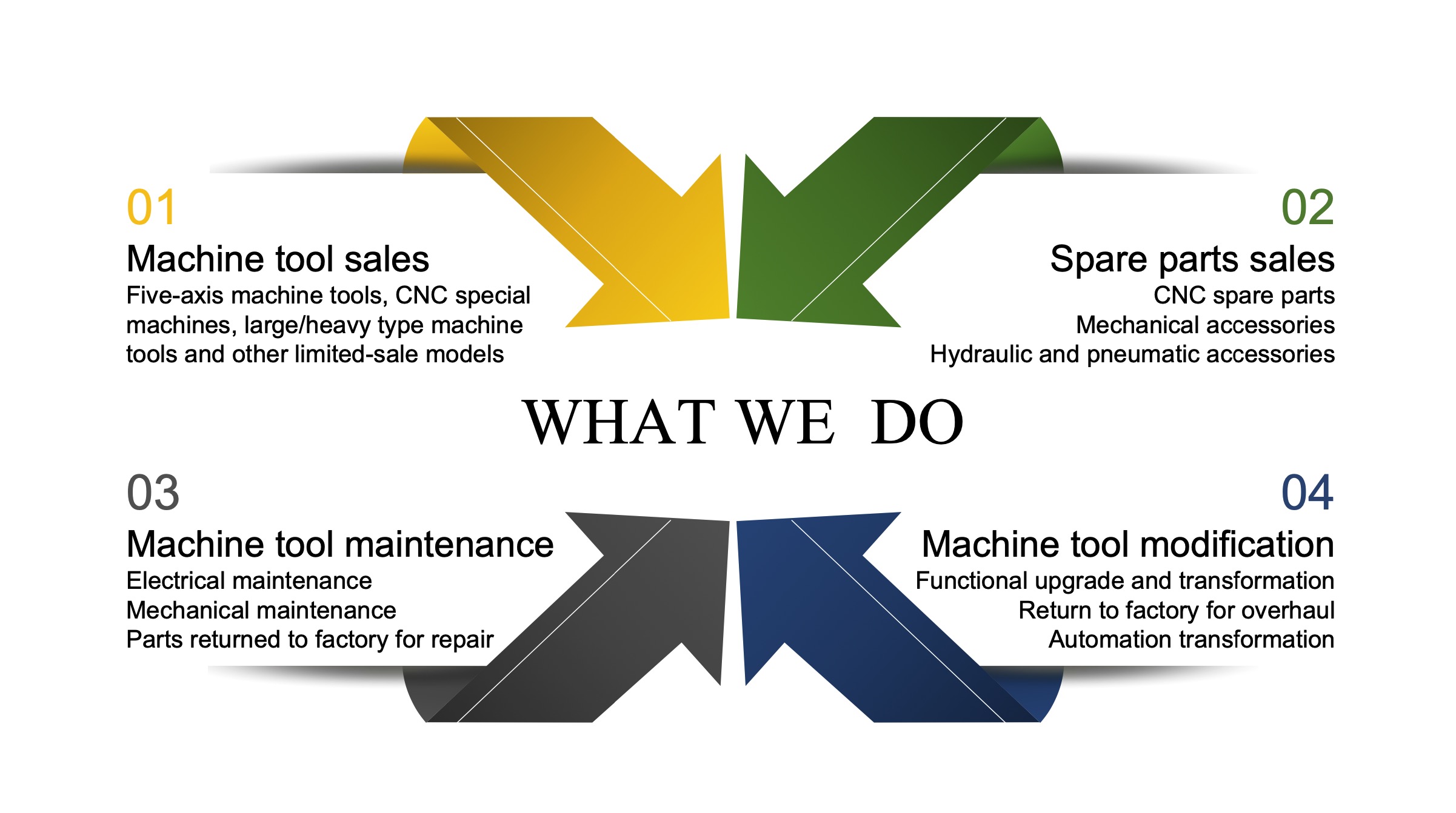

In view of the demand for transformation and upgrading of the manufacturing industry, Z-source Technology (Hong Kong) Limited. selects CNC machine tool products from top domestic and foreign brands, covering multiple fields such as precision processing and intelligent manufacturing. We not only provide high-quality equipment, but also provide professional technical support and after-sales service to help manufacturing companies improve production efficiency and achieve product upgrades.

- Machine Tool Modification (Independent & Controllable)

Overview

- 1. Functional Upgrade: Installation of tool setters, probes, collision protection devices, and 4/5-axis additions

- 2. Factory Overhaul Modification: Complete equipment refurbishment, precision restoration and electrical upgrades

- 3. Automation Modification: Configuration of robotic arms for automatic tool changing or unattended automated processing

Functional Upgrade

According to the actual processing tasks of the machine tool, the machine tool is equipped with a tool setter, a probe, a collision protection sensor, and a 4/5-axis turntable to expand the processing capacity of the original machine tool and make the machine tool production more efficient and safer.

| Title | Description |

| Renishaw probe RMP60 | For automatic alignment and measurement inside the machine, reducing auxiliary downtime and improving machine utilization |

| Renishaw tool setter TS27R | For automatic tool setting inside the machine, automatically judging tool wear and compensating machining paths |

| Montronix Collision protection | For high-precision machines, especially five-axis machines, reducing collision damage from misoperation |

| 4/5 Axis turntable | For expanding machine motion control axes, enabling multi-surface processing with single setup |

Factory Overhaul Modification

For old machine tools that have been in disrepair, especially large/heavy machine tools, the cast iron bed has high precision and stability, but the electrical part .The parts are aging, there are many occasional failures, and the machine bed is obviously worn. We can provide services such as returning the entire equipment to the factory for scraping, precision repair, and electrical upgrades to complete the remanufacturing of the machine tool and fully utilize the basic performance of the old machine tool.

Automation Modification

For batch repetitive processing scenarios, industrial robots can be provided to help complete automation upgrades and achieve unattended automated processing. For large/heavy machine tools, manipulators can be equipped to realize automatic tool changing outside the machine, expand tool capacity, and achieve long-term continuous automated processing. Unattended automated processing units using robots from brands like FANUC, ABB, and KUKA for automatic loading/unloading. External automatic tool changing systems to expand the original tool magazine capacity.